|

|

|

| |

|

| |

|

Don't worry about fouling & corrosion

With decades of experience in cathodic (corrosion) protection of steel structures and marine growth prevention ( for box

coolers and sea water intakes), we have been enjoying high reputations around the world for our expertise and knowhow.

Supplemented by worldwide services and marketing distribution networks, we are a leading international supplier in

this field. For our core technological products (ICCP and ICAF/MGPS), they are the ultimate and most economical

solutions against corrosion and fouling.

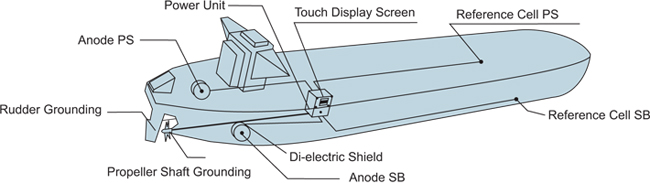

Impressed Current Cathodic Protection Systems (ICCP)

| |

Impressed Current Cathodic Protection (ICCP) system from Corrosion & Water-

Control (CWC) , which utilizes the principle of shifting the natural potential of

metals, protects your ship durably and effectively against corrosion. This ICCP

system provides the ships with all round protection, including the protection for

the propulsion and rudder systems.

All the submerged metal parts of the vessel with the damage or ageing of coatings

are effectively protected by our ICCP system. A clear indication of your

coating's condition will be shown on our Touch Screen Display. All data can be

downloaded to an external computer and transferred by internet for checking .

System adjustment can also be made via the same procedure by uploading. |

|

Advantages of ICCP Power unit

- Touch display operation in all main languages

- “Off potential” controlled

- Coating condition indicator

- Propeller shaft monitoring (+ alarm function)

- Automatic system scan

|

- Down-/uploading via Windows hyper-terminal (internet)

- Automatic / Manual Mode

- History of all data in years

- 3 points temperature check of the cabinet (+ alarm function)

- Connectable to Ship Management System via RS485 and RS232 (Optional)

|

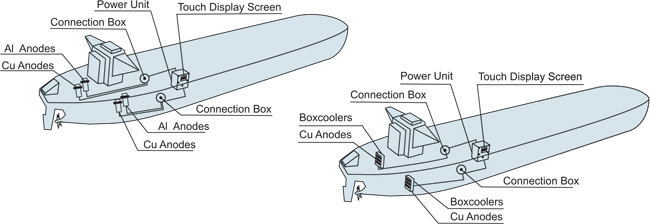

Impressed Current Anti-Fouling Systems (ICAF) /Marine Growth Prevention System (MGPS)

for Sea water intake / Boxcoolers

|

|

|

Sea water intake pipe-work / Box coolers

are always potential fouling victims.

Removing this kind of bio-fouling in the

pipe-work systems invariably increases the

maintenance costs considerably, and it also

affects heat transfer functions for the Box

coolers. Ships sailing in coastal water are

at the greatest danger. Our Impressed

Current Anti-fouling (ICAF) system / MGPS

is the best option to prevent this kind of

fouling . |

|

The copper anodes of our ICAF/MGPS system mounted in the sea chest or strainer are connected to the Power Unit. This

Power Unit has a complete set of controlling functions and guarantees the amount of dissolved copper as required

into the seawater is minimum. The lifetime of anodes is prolonged to the maximum and the perfect protection is assured

under all conditions . In most of the cases , along with the copper anodes, aluminium or soft iron anodes must be

installed to protect the pipe-work against corrosion. |

| |

| |

|

Advantages of ICAF / MGPS Power Unit

|

- Touch display operation in all main languages

- Automatic correct installation check (+ alarm function)

- Remaining lifetime of the anodes (+ alarm function)

- Interactive with seawater pumps via several digital

|

- inputs to save anode material

- Down-/uploading via windows hyper-terminal (internet)

- History of all data in years

- Low voltage / short circuit (+ alarm function)

- Polarity check for anode identification (+ alarm function)

- Connectable to ship management system via RS485 &

RS232 (optional)

|

Sacrificial Anodes

|

Cathodic protection can also be achieved by a more traditional way, namely

sacrificial anodes. This method is to connect the protected metal structures

with a more active metal or alloy. When two metals are electrically connected

to each other in an electrolyte (e.g. seawater), the more active metal (anode)

supplies current and dissolves (sacrifices) to effectively protect the other

metal (structures).

Sacrificial anodes are cast with high efficiency alloys and featured by light

weight and high amperage output. They can function economically and

efficiently without any maintenance during the operating period to control

the corrosion. Furthermore, after installation there are no labor costs

involved and no electrical supply is required. |

| |

|

Application

|

|

- Ships

- Harbor installations

- Offshore engineering

- Underground structures

|

- Tanks

- Power plants , refinery and chemical plants

- Reinforced concrete structures and buildings’ piling foundation

|

On-/Offshore and Harbor Structures Protection

Seawater / water is a natural electrolyte of high corroding rate. On-/offshore

and harbor structures submerged in seawater / water or buried in the

ground are at the serious threat of corrosion , which challenges the safe

operation. These structures frequently have an expected service life of

decades. To survive, the structures must be protected from corrosion with

our Impressed Current Cathodic Protection (ICCP) system or sacrificial

anodes.

We developed an ICCP system, in which the size and shape of the Ti-MMO anodes are tailor made in a unique way due to the different structures to be protected. As a result , these tailor made anodes are easy to install and meet the design of different structures. |

|

|

| For more information please visit www.corrosion.nl. |

| |

|

| |

|

|

Disclaimer :

Information and photographs in this catalogue are an overview of OEM range products. For more / exact details please refer to original OEM catalogue. Products names, logos, brands and other trademarks featured or referred to within this document are the property of their respective trademark holders. |

|